As the holiday season approaches, a long-standing Kentucky factory prepares to power down for good. Leggett & Platt—a 140-year-old name in American furniture—will permanently close its adjustable bed plant in Georgetown, cutting between 100 and 122 jobs.

The company confirmed in a September notice that layoffs will begin this November and continue into early 2026, a decision that looms over dozens of families heading into what should have been a season of comfort and certainty.

Company Cites ‘Difficult Business Conditions’

In a letter to the Kentucky Education and Labor Cabinet dated September 10, the Missouri-based manufacturer attributed the decision to “difficult business conditions” and a drive for “operational efficiency.” The document fulfills requirements under the federal WARN Act, which ensures affected employees receive at least 60 days’ notice.

Though routine in format, the message was sobering: the Georgetown facility, once a quiet source of dependable income for dozens of families, will soon fall silent.

Layoffs Begin in November

The first wave of layoffs begins around November 10, primarily affecting production and support workers. Additional rounds will continue into 2026 as operations wind down in stages.

For workers who have spent years assembling adjustable bed frames on Georgetown’s Summer Court, the approaching winter now brings not only colder weather but also job loss. “We’ve been through ups and downs, but this feels different,” one long-time employee told WKYT, reflecting a growing sense of unease.

Workers Across Roles to Be Affected

The WARN notice detailed that roughly 90 production and support employees, six clerical staff, and four managers will lose their positions. The plant’s closure hits a workforce that has grown close over time—many describe it as a “family atmosphere,” forged over shared shifts and steady paychecks.

For a town like Georgetown, where manufacturing remains a key economic pillar, the ripple effects extend far beyond the factory walls.

Commitment to Efficiency and Support

In the filing, Michael Altman, Leggett & Platt’s director of employee and labor relations, said that the decision aligns with the company’s broader goal to “enhance operational efficiency.”

He added that the company would explore outplacement programs to help affected workers transition to new roles. While such efforts are appreciated, they can’t fully offset the emotional toll of losing a steady paycheck—especially during a season when financial burdens tend to climb.

A Key Piece of the Firm’s Bedding Operations

The Georgetown facility has long been part of Leggett & Platt’s bedding division, which designs adjustable bases for major mattress retailers across the country. Its workers have supplied components that are used in homes and hotels nationwide.

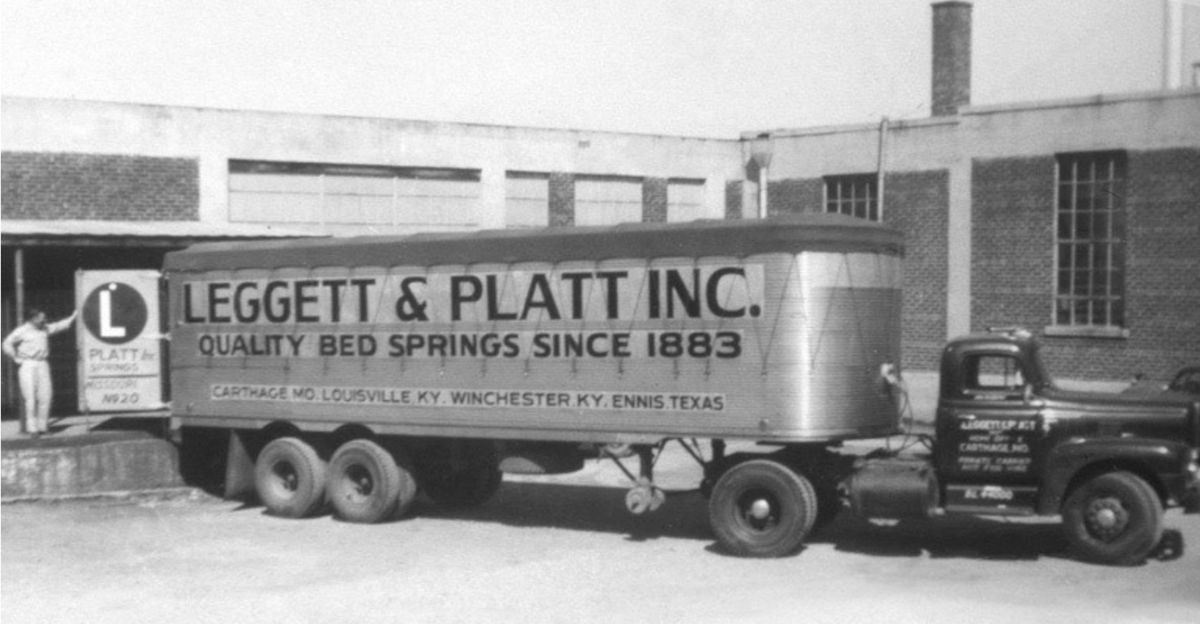

Founded in 1883 and headquartered in Carthage, Missouri, the company operates more than 130 plants globally and employs over 17,000 people, according to public filings. Each local closure represents more than a line on a balance sheet for a firm with such reach—it’s a community story.

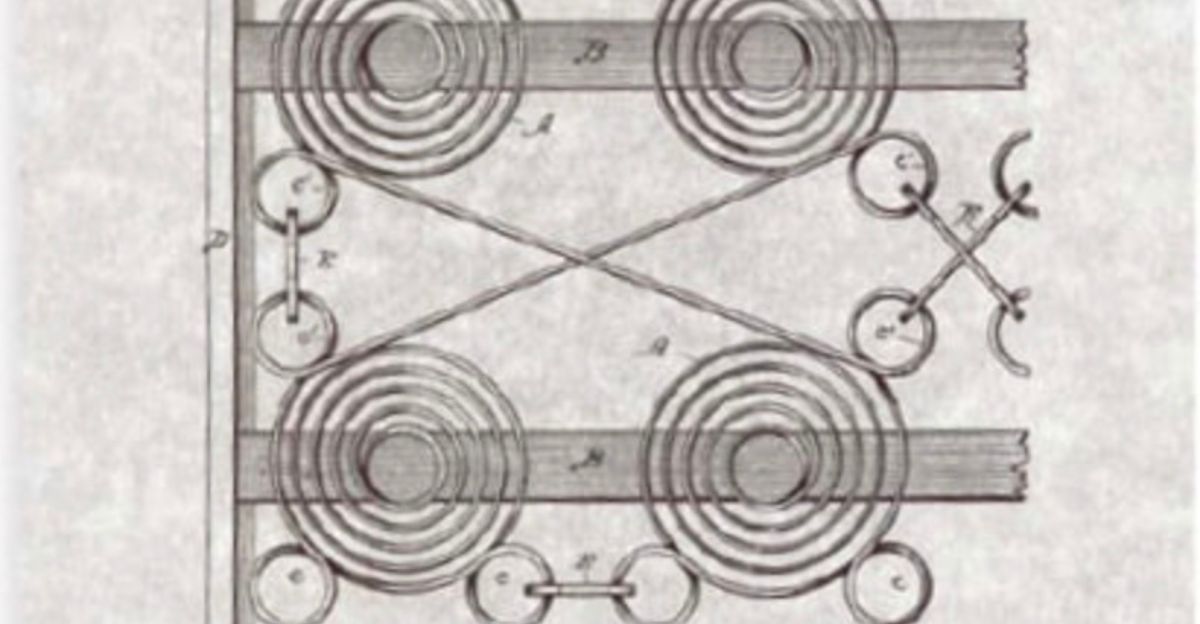

A Legacy Built on Furniture Innovation

Leggett & Platt’s legacy stretches back over a century, when its founders patented a new type of bedspring that transformed modern bedding. The Georgetown plant carried that spirit of craftsmanship, producing adjustable bed frames known for durability and comfort.

Many employees took pride in seeing their work featured in major retail stores. “You’d walk into a showroom and think, ‘I helped make that,’” one former worker told Lex 18. “That was something to be proud of.”

A Broader Corporate Restructuring Plan

The Kentucky plant’s fate was sealed as part of a sweeping corporate restructuring. In early 2024, Leggett & Platt’s board approved plans to cut 900 to 1,000 jobs across North America, citing a need to streamline operations amid slower consumer demand.

The initiative affected multiple divisions, from home furniture to automotive components. Industry analysts said the move would stabilize long-term growth, though it would inevitably bring short-term pain.

Restructuring Aims to Align With ‘Evolving Landscape’

Cassie Branscum, the company’s vice president of investor relations, said the restructuring sought to “align our business with an evolving competitive landscape” and “position our company for profitable growth.” For Kentucky, that means Georgetown’s loss becomes another plant’s gain.

Production from the adjustable bed division will shift to other U.S. facilities, where automation and consolidation promise greater cost savings—a trend seen across many manufacturing sectors.

Holiday Timing Raises Concerns for Local Families

The timing has hit especially hard in Scott County. Local leaders say the layoffs will impact dozens of families heading into the holidays, when household budgets are already stretched thin. “This couldn’t have come at a worse time,” one city official told The Georgetown News-Graphic.

Roughly one-third of affected employees will be out of work before Christmas, turning what’s usually a time of celebration into a season of financial anxiety.

Reduced Demand and Tariffs

According to The Courier Journal, Leggett & Platt cited softening customer demand and lingering tariffs on imported materials among the key pressures on the Georgetown operation. Global supply disruptions and higher costs for steel and electronics—components central to adjustable bed frames—have squeezed margins.

Similar struggles have dogged U.S. furniture makers since 2023, leading many to consolidate facilities or shift production offshore.

Broader Industry Headwinds Hit U.S. Furniture Makers

Industry experts say the Georgetown closure reflects a broader trend. Furniture producers across the country are wrestling with fluctuating raw material prices, slower housing starts, and shifting consumer spending.

“We’re seeing a structural reset in how Americans buy and value furniture,” said analyst Jerry Epperson of Mann, Armistead & Epperson, speaking with Furniture Today. “Online competition and import pricing are rewriting the old playbook.”

Production Consolidation

Leggett & Platt said production from Georgetown will be absorbed into other U.S. facilities as part of its cost-efficiency push. Company filings show bedding-sector sales have declined for four consecutive quarters, a slide executives hope to counter by concentrating output at higher-volume plants.

For remaining employees elsewhere in the company, consolidation brings opportunity and pressure—to do more with less and maintain quality standards while costs tighten.

Local Support Networks Step In

Scott County officials are partnering with the Kentucky Career Center to provide retraining, résumé assistance, and career counseling. “We want to make sure every displaced worker has access to resources that can help them get back on their feet,” a local workforce representative said.

While these programs offer vital support, no relocation incentives or state grants have yet been announced, leaving many families unsure how long they can hold out financially.

Manufacturing Layoffs Reflect a National Trend

The Georgetown plant’s shutdown is part of a larger national pattern. Throughout 2025, U.S. manufacturers have announced a string of closures in sectors ranging from agricultural equipment to electronics. Economists say these job cuts reflect waning industrial confidence heading into 2026.

In September, the Institute for Supply Management reported that U.S. factory activity had contracted for a twelfth consecutive month—a troubling sign for blue-collar communities reliant on steady production work.

Long-Term Stability Projected

Despite near-term losses, Leggett & Platt remains profitable. Corporate projections filed with the SEC anticipate around $4.3 billion in annual revenue by 2028. Executives say the restructuring will help offset inflationary pressures and align production with future demand.

It’s a classic corporate balancing act—protecting long-term stability while navigating short-term hardship for the people behind the numbers.

A Global Footprint Under Financial Pressure

The company’s footprint extends well beyond Kentucky, with major plants in Mississippi, North Carolina, and Mexico now absorbing Georgetown’s production lines. Consolidation, the company says, allows for greater flexibility and cost control.

Analysts note that such shifts highlight a deeper tension between maintaining American manufacturing roots and competing globally with cheaper labor and materials.

Competition and Steel Prices Squeeze Profit Margins

Rising steel costs and foreign competition continue to erode profit margins across the industry. The volatility has pushed U.S. furniture makers, including Leggett & Platt, to invest heavily in automation to reduce labor costs.

While such moves may safeguard future profits, they often come at the expense of smaller communities built around local factories—communities like Georgetown, where tradition and industry have long been intertwined.

Community Feels the Loss Beyond the Factory Floor

For Georgetown residents, the closure represents more than just lost jobs—it’s the erosion of a shared identity. Many workers have spent over a decade on the factory floor, forging friendships that stretch far beyond the time clock.

Local churches and nonprofits are preparing food drives and support programs, anticipating an uptick in need as the layoffs progress. One worker told The Lexington Herald-Leader, “It’s not just the paycheck we’ll miss. It’s the people.”

Balancing Efficiency With Human Impact

Leggett & Platt’s restructuring may ultimately strengthen its financial outlook, but its short-term consequences are deeply personal. As holiday lights begin to glow across Georgetown, dozens of families now face hard choices—rent or gifts, groceries or gas.

The story unfolding here is one of quiet resilience, shared by countless American towns where corporate efficiency meets human cost—and where community remains the last, steadfast thing holding people together.