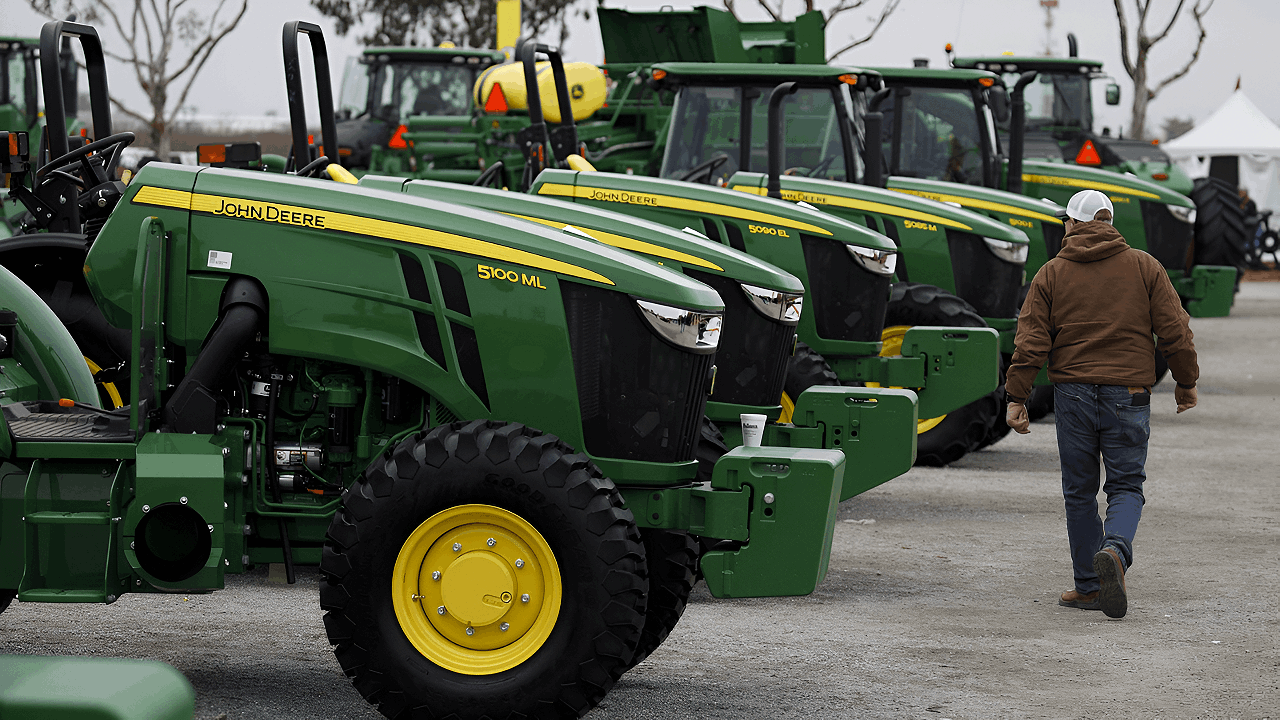

One October morning, the machinery line at a John Deere plant in Iowa slowed to a halt. Supervisors gathered small groups of workers and delivered the news: 141 positions were being eliminated. Some stood in disbelief, others quietly cleared their lockers. Outside, pickup trucks idled as employees made anxious calls home—another blow to Iowa’s manufacturing heartland amid falling demand for farm equipment.

What forces are driving America’s top tractor maker to cut jobs after decades of steady growth?

Economic Headwinds

The agricultural equipment industry is struggling under severe economic pressures. Falling crop prices, fluctuating fuel costs, and lower farm incomes have led to widespread cutbacks in equipment purchases.

As farmers tighten spending, major manufacturers like John Deere are feeling the squeeze, prompting layoffs and plant slowdowns across the Midwest. It’s part of a domino effect linking global commodity trends to local employment stability.

A Storied Legacy Tested

For nearly 190 years, John Deere has symbolized American craftsmanship and innovation. Yet since 2015, the company has eliminated over 4,500 U.S. jobs, reflecting the broader decline of domestic manufacturing.

Once a steady employer for generations, Deere now faces the same global cost-cutting pressures that have pushed many U.S. industries to relocate or automate. The shift challenges the company’s long-standing reputation for stability.

The Price of Commodities

A sharp drop in farm commodity prices has rippled through the agricultural supply chain. As corn and soybean prices fall, farmers postpone major purchases, directly reducing demand for tractors and harvesters.

For John Deere, that means fewer orders and declining revenue. With its core market shrinking, the company has had to reduce production output and cut costs—starting with its workforce.

October Layoffs Hit Iowa

In October 2025, John Deere confirmed layoffs affecting 141 employees at its Waterloo and Ankeny plants. The cuts come amid a broader restructuring effort tied to weakening demand for agricultural machinery.

For Iowa, where Deere is a cornerstone employer, the announcement deepened concerns about job losses and long-term economic recovery. It’s part of an ongoing pattern of workforce reductions across multiple Deere facilities.

The Local Shockwave

Layoffs in Iowa reverberate far beyond factory floors. Local diners, hardware stores, and supply chains depend heavily on Deere’s workforce.

When jobs vanish, spending slows, and small businesses struggle to stay afloat. Economists estimate each lost manufacturing job can impact up to five additional local roles, compounding the regional economic strain. For many Iowa communities, these cuts strike at the heart of their economic identity.

Lives in Transition

The human toll is mounting. Displaced employees face dwindling job options in regions where industrial work once offered lifelong stability.

Many workers remain skeptical about future opportunities as automation advances and more production shifts abroad. Workers fear these layoffs are not temporary setbacks—but permanent signs of industrial decline.

Industry-Wide Strain

John Deere’s challenges mirror those across the agricultural machinery sector. Rivals like CNH Industrial and AGCO are also scaling back production amid sluggish global demand.

Farmers, facing higher interest rates and unpredictable weather, are opting to rent or maintain existing machines rather than buy new ones. The result: manufacturers are tightening budgets, slowing production, and cutting jobs to remain financially sustainable.

Trade Policy Complications

Trade uncertainty continues to cloud the outlook. Tariffs on steel, aluminum, and imported components have inflated production costs for manufacturers like Deere.

Shifting global trade deals, combined with volatile export markets for U.S. crops, make long-term planning increasingly difficult. These conditions have pushed many companies to seek cheaper labor and materials abroad—decisions that carry steep social and political costs at home.

Production Moves South

Deere has confirmed it will relocate production of skid steer loaders and compact track loaders from Dubuque, Iowa, to Mexico by late 2026. The company says the move will streamline operations and reduce costs.

While Deere maintains it will reinvest in U.S. facilities, the announcement underscores the growing appeal of lower-cost manufacturing abroad—especially as inflation and labor costs rise domestically.

Community Backlash

The decision has sparked frustration and disappointment in Iowa. Workers, local leaders, and residents say Deere’s move undermines decades of loyalty from employees who built the company’s global reputation.

Many view the shift as prioritizing corporate profits over community well-being. Protestors and union representatives have called for greater transparency about future layoffs and for reinvestment in U.S. manufacturing jobs.

Deere’s Official Response

Company executives insist John Deere remains committed to American manufacturing. Leaders point to a $20-billion plan to modernize U.S. facilities over the next decade, citing ongoing investments in automation, sustainability, and plant upgrades.

Deere argues that modernization—not abandonment—is key to staying competitive globally. Still, critics question whether these promises can offset the effects of thousands of jobs moving abroad.

Investing to Adapt

Deere’s modernization push includes robotics, smart assembly lines, and AI-driven production systems. The goal is to increase efficiency and reduce operating costs without fully exiting U.S. markets.

By integrating advanced manufacturing technologies, Deere hopes to future-proof its business while navigating an increasingly digital global economy. Whether these investments can meaningfully replace lost jobs remains an open question.

Analysts See a Long Game

Industry analysts believe Deere’s short-term challenges may yield long-term gains if managed strategically. By diversifying production and improving efficiency, the company could emerge stronger once agricultural markets rebound.

However, they caution that recovery depends on global demand, trade stability, and how effectively Deere balances innovation with employee retention and public trust. The coming years will test that balance.

Balancing Global Strategy

Deere’s strategy reflects a balancing act: cutting costs abroad while maintaining a U.S. presence vital to its brand identity.

Executives argue that operating internationally allows the company to stay competitive and support American jobs indirectly. Yet, critics warn that too much outsourcing risks hollowing out the domestic industrial base that once defined Deere’s success and community impact.

Political Fallout

The decision to move manufacturing to Mexico has sparked political tension. Lawmakers from agricultural states have criticized Deere’s move, warning it could trigger new tariffs or strain U.S.–Mexico trade relations. Manufacturing jobs have become a flashpoint in debates over globalization, economic security, and the future of American industry.

A Global Trend Accelerates

John Deere’s restructuring is part of a larger shift in global manufacturing. Since 2018, more than $226 billion in annual manufacturing has relocated from China to Mexico and other low-cost countries, according to Alvarez & Marsal research.

This massive migration—what some analysts call a $200 billion-scale manufacturing retreat from traditional offshore hubs—reflects decades of offshoring trends intensified by recent inflationary pressures, reshaping where and how goods are made and challenging the notion of “Made in America.”

Legal and Trade Risks

While offshoring promises cost savings, it also brings legal and trade risks. If new tariffs target products made abroad, Deere could face higher import costs or logistical bottlenecks. Trade disputes and shifting international regulations could further complicate operations, forcing the company to continually adjust its global manufacturing strategy to avoid costly disruptions.

The Cultural Shift

Deere’s layoffs highlight a deeper cultural transformation. As U.S. economies transition from manufacturing to services and technology, traditional factory towns are struggling to redefine their purpose.

Generations raised on industrial stability now face an uncertain economic future. The story of Deere’s workforce reflects a broader question: what happens when America’s most iconic industries no longer anchor its middle class?

A Mirror of Modern Industry

John Deere’s evolving story encapsulates the contradictions of modern capitalism. Even after reporting record profits of $10.166 billion in fiscal 2023, the company is cutting jobs and moving production abroad—an uneasy balance between shareholder value and worker livelihoods.

As global efficiency reshapes local realities, Deere stands as both a symbol of industrial success and a mirror reflecting the costs of progress in a globalized world.